At cind we are dedicated to provide data capturing solutions through software and sensor technology to enhance our customers' logistics performance.

“To measure is to know.”

Physicist William Thomson "Lord Kelvin"

Are you within:

Forestry?

Our solutions for delivery control of roundwood and wood chips. Widely installed in Sweden and other parts of Europe.

- READ MORE -

Logistics?

Explore our solutions and how we help companies within transportation and air cargo.

- READ MORE -

Benefits

#1 Adding intelligence beyond human capabilities

We provide intelligence to enable data-driven decision making. Gain valuable insights and drive performance improvements.

#2 Digitizing labor intensive tasks

We help companies digitize tasks, reducing manual workloads and enhancing operational efficiency.

#3 Earnings retrieval

Our solutions ensure precise invoicing and enable new revenue opportunities.

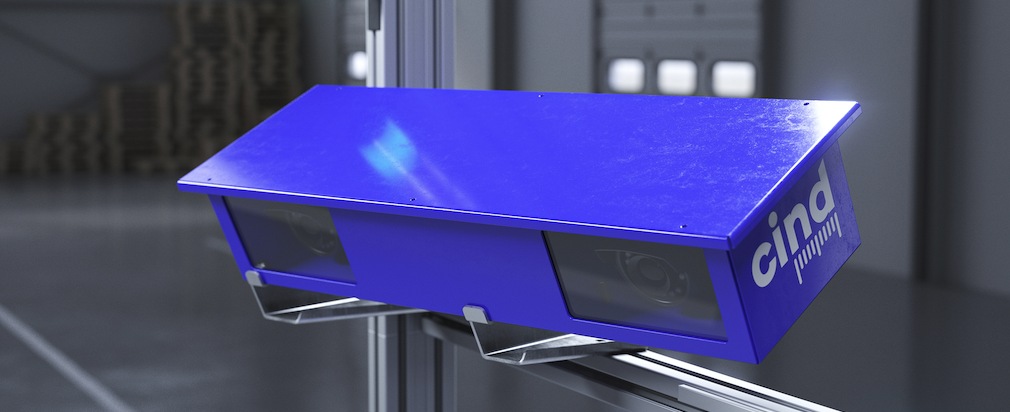

#4 Stereo-vision technology

Cameras gather extensive data in real-time, dynamic, and without any additional effort. Compared to other methods such as human workforce or laser technology.

Our solutions

CargoSpect

In-motion pallet dimensioning

- READ MORE -

ContourSpect

Virtual Contourcheck - ULD pallet build up

- READ MORE -

TimSpect

Automated volume measurement roundwood

- READ MORE -

“We chose CIND because of their unique stereo camera technology. Partly for the compact camera equipment solution, partly because of the innovative development possibilities that automatic volume calculation of pulp wood stacks on a vehicle provides.”

Stig Jonsson, Senior Specialist Wood Logistics at BillerudKorsnäs

News and stories

-

Open position - Chief Sales Officer (In swedish)

Just nu letar vi efter en erfaren och passionerad Chief Sales Officer som är redo att bli en nyckelspelare i vårt internationella expansionsteam.

-

Customer succes - WFS

Ready? Let´s roll 🎬

🔵 A digital solution that makes all air cargo pallets 100% fit to fly!

From Copenhagen Airport, Kastrup, showcasing our ContourSpect project together with Worldwide Flight Services (WFS) -

Office tour

Check out our office, take the virtual tour!

-

ContourSpect: WFS pressrelease

Worldwide Flight Services (WFS), a member of the SATS Group, will deploy Cind’s ContourSpect 3D modelling software at selected stations across its Europe, Middle East, Africa, and Asia (EMEAA) network following a successful Proof of Concept (POC) in its cargo terminal at Copenhagen Airport.

-

New customer

CIND and Småland Timber AB have signed an agreement

-

Country manager Germany

Hello Germany

Kerstin Meyer joined our team earlier this year as Country Manager Germany!

Ready to take action?

Get in touch with us!